Electropolishing Stainless Steel Industries Served

Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

What are the industries that can benefit from electropolishing & passivation services?

At Electro-Max, Inc., we can provide electropolishing and passivation services to the following industries, listed below!

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

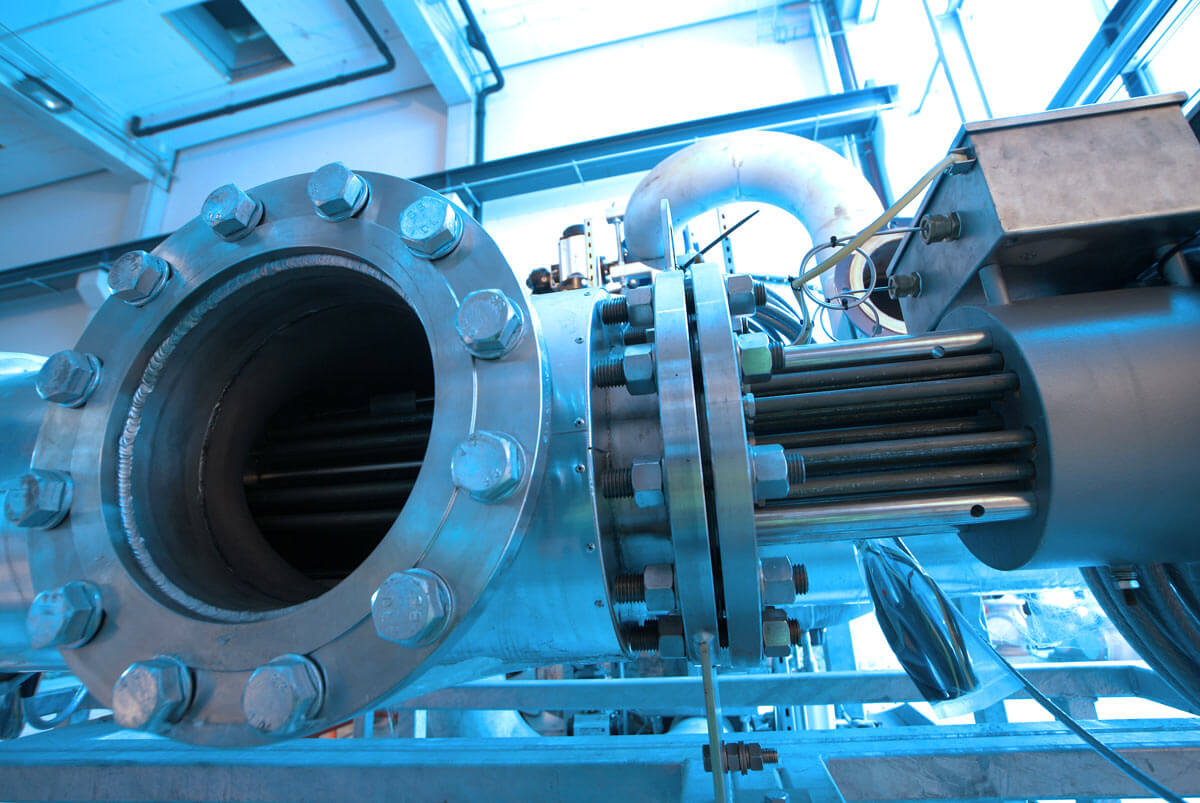

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn More

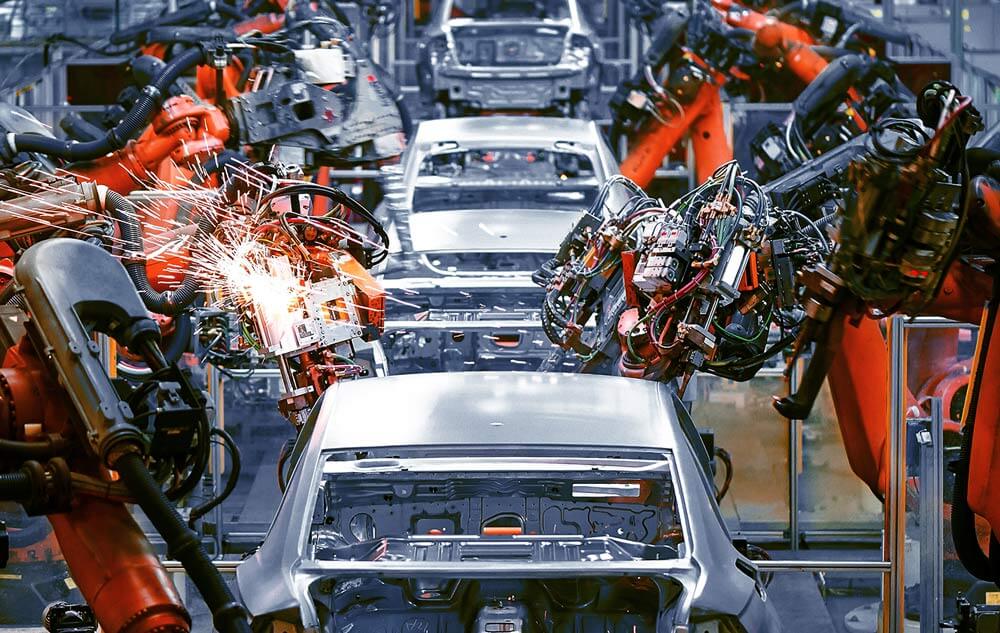

Automotive

In the dynamic realm of automotive engineering, precision, durability, and top-tier performance are imperative. To meet the rigorous standards of the Automotive industry, the specialized processes of auto parts electropolishing and automotive parts passivation are crucial.

Learn More

Marine

Stainless steel is heavily utilized in the marine industry and is constantly exposed to some of the harshest environments known to man. Passivation and electropolishing processes will give your part the durability and longevity required for such harsh conditions.

Learn MoreSemiconductor

Electropolishing services for the semiconductor industry are of the utmost importance due to the processes ability to create an ultra clean piece that can resist the harsh chemicals and processes required.

Learn More

Electronics

Electropolishing or passivation can offer a host of benefits by improving the conductivity of contacts and switches by eliminating surface imperfections that could otherwise affect the products performance by generating resistance.

Learn More

Consumer Appliances

To prevent costly warranty repairs, consumer appliance manufacturers utilize electropolishing or passivation to clear away any surface contaminants leaving the surface heavily resistant to corrosion or contamination.

Learn MoreIndustrial Use of Electropolishing

Certain industries require metal components that can deliver exceptional levels of resistance to corrosion and contamination, even beyond the strength of stainless steel. The solution to this challenge: electropolishing, an electrochemical process in which an electrical current is run through a metal component while immersed in a chemical bath. The chemical reaction on the surface of the part removes a very thin layer of the surface of the material at a uniform rate. The electropolished metal surface is smooth, substantially brighter, and highly resistant to corrosion or contamination.

Aside from improved corrosion resistance, the electropolishing process offers manufacturers additional benefits. It can help improve the surface finish of the material, removing burrs and cleaning welds. Electropolishing can also strengthen the material at a microscopic level, removing microcracks and heat tint and improving the metal’s fatigue life.

Passivation for Numerous Industries

In addition to electropolishing, Electro-Max offers passivation services. During the manufacturing process, many stainless steel components can be exposed to grease, oil and other contaminants that can compromise the chromium oxide layer that gives stainless steel its corrosion resistance. Passivation helps this oxide layer form faster and thicker for improved resistance to corrosion. And unlike electropolishing, passivation doesn’t require electricity and doesn’t change the steel’s appearance.

Industries We Serve

In business since 1998, Electro-Max has risen to become a leading provider of electropolishing and passivation services to numerous industries.

Contact us today to learn more.

Do you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100