Electropolishing

Electropolishing is an electrochemical polishing process that removes surface imperfections including impurities, burrs, and other defects. The reverse plating process creates a smooth surface on metal objects that is microscopically featureless. This type of metal finishing process leaves parts ultraclean, micro-finished, and corrosion protected. The Electropolishing process can be done on stainless steel and other metal alloys. As an electropolishing and passivation metal finishing company, Electro-Max, Inc. is ready to suit your needs!

Passivation

What is Passivation? Passivation is a non-electrical metal finishing process to help prevent metal surfaces from corrosion and pitting. The chemical treatment for stainless steel and other alloys makes the metal more resistant to rust and reduces chemical reactivity.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

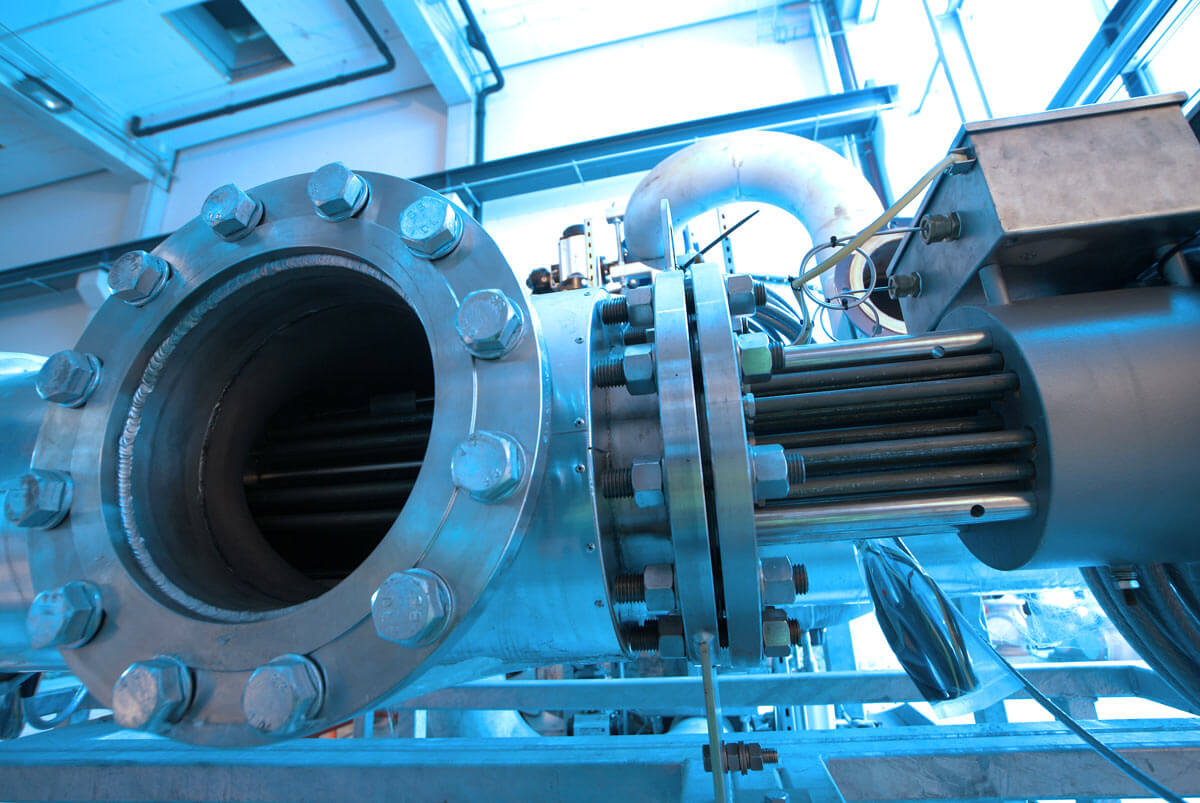

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDiscover Our Value-Added Services

Speciality Packaging

What is Specialty Packaging Services for Metal Finishing?

Proper packaging helps to prevent corrosion and keep parts free of damage. Appropriate packaging is a smart investment for parts that are sensitive to corrosion and will be stored in conditions that expose them to moisture, chemicals and temperature fluctuations.

Using EMI for your special packaging needs can save time and money by freeing up internal resources, reduce waste by minimizing or eliminating part damage that could happen during transit.

Vapor Blasting

Vapor blasting (also known as wet blasting, liquid honing, or dustless blasting) is a process that uses pressurized water and abrasive material to remove contaminants, corrosion, residue or coatings from a surface. The vapor blasting process provides the highest quality soft surface finish. It is commonly used for cleaning aerospace parts and surfaces.

Weld Descaling

Weld descaling is the removal of heavy, tightly adherent oxide films resulting from hot-forming, heat-treatment, welding, and other high-temperature operations. Weld descaling is performed prior to passivation. Continue reading to learn more about Electro-Max, Inc.’s weld descaling and chemical descaling services.

Oxygen Cleaning

Oxygen (O2) chemical cleaning is a chemical cleaning service offered by Electro-Max, Inc. Typically, this oxygen cleaning service is performed on products that are intended for oxygen-enriched and high purity environments. Other applications include hydrogen and nitrogen-enriched environments as well as other various liquid and gas applications. This process provides the removal of any residual organic and inorganic contamination such as hydrocarbons, which include weld slag, oils, greases, and more. Furthermore, a passive layer surface is left which reduces particulate contamination while inhibiting oxidation.

Stainless Steel

Finishing Services & Company

Why Choose Electro-Max, Inc. As Your Stainless Steel Finishing Services Company?

EMI offers Stainless Steel Finishing Services, and we specialize in the finishing of stainless steel through a process called electropolishing and passivation. Electro-Max also offers complimentary services such as stainless steel pickling and degreasing. Our goal is to become your only source for metal finishing services by providing superior customer interaction, excellent value, and top-notch quality. With our validated processes we are one of only a few in the U.S.A. able to offer Nadcap-approved electropolishing. Make Electro-Max, Inc. your go-to electropolishing and passivation metal finishing company today!