Pharmaceuticals & Bio-Processing Electropolishing & Passivation Services

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable. Stainless steel and other metals and alloys are foundational materials in these sectors, and to ensure they meet the rigorous standards, electropolishing and passivation are indispensable. This article dives into why these services are crucial, and why Electro-Max, Inc. is the ultimate choice for the pharmaceutical and bio-processing industry.

Bio-Processing & Pharmaceutical Applications of Electropolishing & Passivation

Bioreactors and Fermentation Vessels

Why are Electropolishing & Passivation Essential for Bioreactors and Fermentation Vessels?

Bioreactors and fermentation vessels are at the heart of pharmaceutical and bio-processing operations. These components need to maintain a pristine environment to prevent contamination and ensure the purity of biologically active compounds. Electropolishing and passivation create a smoother, more hygienic surface, which is critical for maintaining product purity and preventing contamination.

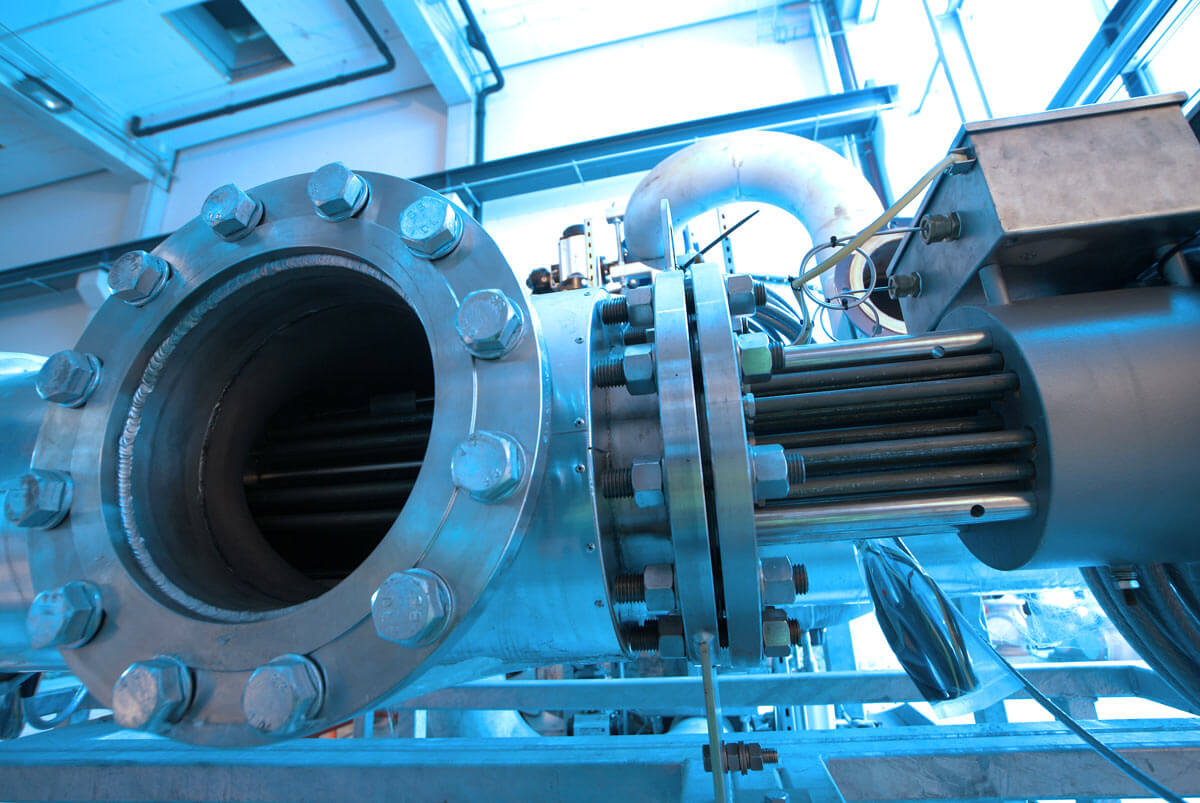

Tubing and Piping Systems

Why are Electropolishing & Passivation Essential for Tubing & Piping Systems?

Tubing and piping systems are the arteries and veins of pharmaceutical and bio-processing facilities. These systems must be corrosion-resistant, easy to clean, and resistant to bacterial adhesion. Electropolishing and passivation enhance the corrosion resistance and microbiological cleanliness of these systems, ensuring product quality and safety.

Pharmaceutical and Bio-Tec Equipment

Why are Electropolishing & Passivation Essential for Pharmaceutical & Bio-Tech Equipment?

Various equipment, including mixing tanks, storage vessels, and valves, must adhere to stringent hygiene and quality standards. Electropolishing not only enhances corrosion resistance but also improves aesthetics, making it easier to clean and sterilize equipment. This is vital in maintaining product purity and safety.

The Benefits of Electropolishing in Pharmaceutical & Bio-Tec Applications

What are the Benefits of Electropolishing Pharmaceutical & Bio-Tec Applications?

- Enhanced Corrosion Resistance: Electropolishing takes the natural corrosion resistance of stainless steel and elevates it. This is crucial in environments where aggressive chemicals and cleaning processes are employed.

- Microbiological Cleanliness: The smoother surface created by electropolishing makes it challenging for bacteria and microorganisms to adhere. This is vital in environments where sterility and contamination control are paramount.

- Improved Aesthetics: Beyond functionality, electropolishing enhances the appearance of stainless steel components, making them visually appealing and easier to maintain.

Why Choose Electro-Max, Inc. for Bio-Processing & Pharmaceuticals Electropolishing & Passivation Services?

ASME BPE 2016 Certification

Electro-Max, Inc. is proud to be certified to ASME BPE 2016, a certification designed specifically for the bioprocessing equipment industry. This certification ensures that our electropolishing and passivation processes meet the highest industry standards, contributing to product safety and quality.

Specialization in Electropolishing and Passivation

Electro-Max specializes in the finishing of stainless steel and other materials through electropolishing and passivation. Our team possesses extensive knowledge and experience in these processes, guaranteeing the best results for clients in the Pharmaceutical and Bio-Tec industry.

Comprehensive Services

In addition to electropolishing and passivation, we offer complementary services such as stainless steel pickling and degreasing. This comprehensive approach ensures that all your metal finishing needs are met under one roof, streamlining your project and saving you time and effort.

Dedicated to Customer Satisfaction

Electro-Max, Inc. is dedicated to superior customer interaction, value, and top-notch quality. We understand the critical nature of your projects and work tirelessly to ensure your complete satisfaction.

The pharmaceutical and bio-processing industry demands the highest levels of precision, hygiene, and quality. Electropolishing and passivation are vital processes in achieving these goals. When you choose Electro-Max, Inc., you can trust that your materials will meet the most stringent industry standards. Our ASME BPE 2016 certification, expertise, comprehensive services, and dedication to customer satisfaction make us the premier choice for all your electropolishing and passivation needs in the Pharmaceutical and Bio-Tec industry.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

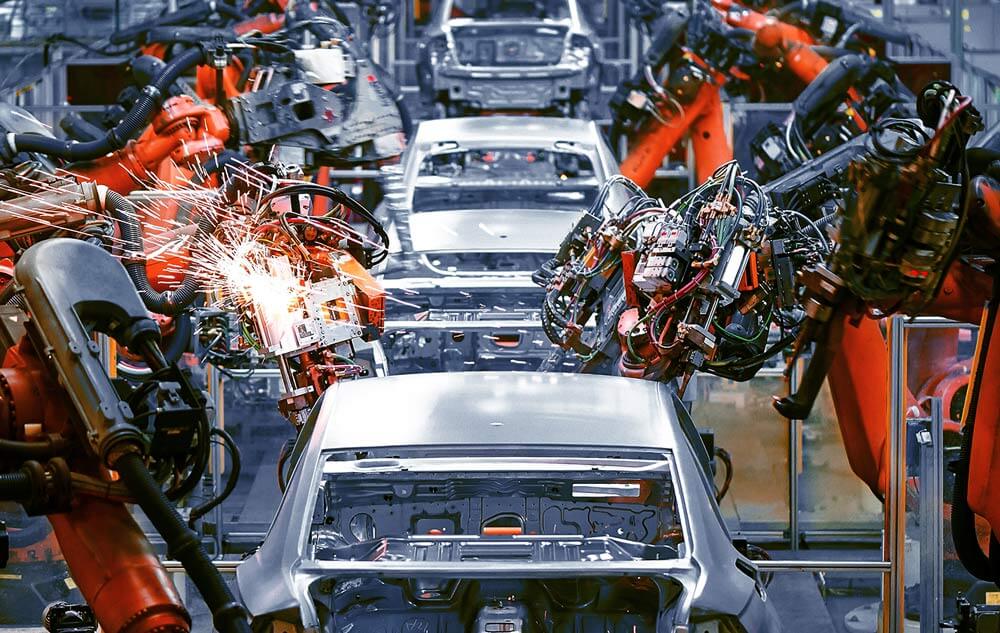

Automotive

In the dynamic realm of automotive engineering, precision, durability, and top-tier performance are imperative. To meet the rigorous standards of the Automotive industry, the specialized processes of auto parts electropolishing and automotive parts passivation are crucial.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100