Electropolishing Application Solutions & Industries Served

What Types of Applications Solutions & Industries Require Electropolishing Services?

Electropolishing is used on parts, components, and equipment from an extensive range of application solutions and industries. High-quality electropolishing services provided by EMI extend the service life of parts, reduce contamination, decrease surface adhesion, and ensure your components deliver the precision and performance you require.

EMI provides electropolishing services, specified to ASTM-B912-00, to meet a variety of applications and industries, including:

- Machined Parts

- Clean Room Components

- Medical Instruments

- Food & Beverage

- Energy Generation Equipment

- Aerospace

- And more!

Electropolishing Machined Parts

One of the many electropolishing application solutions and industries served includes electropolishing machined parts. On machined parts, electropolishing eliminates burrs, relieves surface stress, makes parts easier to clean, reduces corrosion and contamination, and provides an appealing look. Electropolishing is ideal for machined parts such as:

- Screws

- Bolts

- Washers

- Valve stems and bodies

- Pipes and tubing

- Fittings

- Stampings

- Spinnings

- Weldments

- Castings

- Forgings

- Fasteners

- Drawings

- Tanks

- Rods

- Discs

Electropolishing Clean Room Components

Electropolishing clean room components provide a superior, non-contaminating, non-particulating finish for furniture and fixtures used in clean rooms – where hygiene and cleanliness are paramount:

- Tables

- Chairs

- Waste containers

- Lighting

- Exposed electrical conduits

- Outlet boxes

- Processing equipment

Electropolishing Food & Beverage Processing Equipment

Electropolishing provides smooth, easy-to-clean, sanitary, visually appealing surfaces demanded by this industry. Electropolishing reduces oxidation and contamination for a long list of stainless steel food and beverage processing equipment, including:

- Kettles

- Packaging equipment

- Pans

- Wire baskets

- Vats

- Cooking trays

- Racks

- Utensils

Electropolishing Medical Instruments

The medical field extensively uses electropolishing. Almost all hospital, medical, and surgical equipment are electropolished to protect against germs and contamination and make cleaning easier. Electropolishing can be used on lifesaving and health-affirming equipment, including:

- Scalpels

- Covid Vaccine production

- Respirators/Ventilators

- Clamps

- Saws

- Bone and joint implants

- Prosthetic devices

- Burn unit beds

- Rehabilitation whirlpools

- Pharmaceutical manufacturing equipment

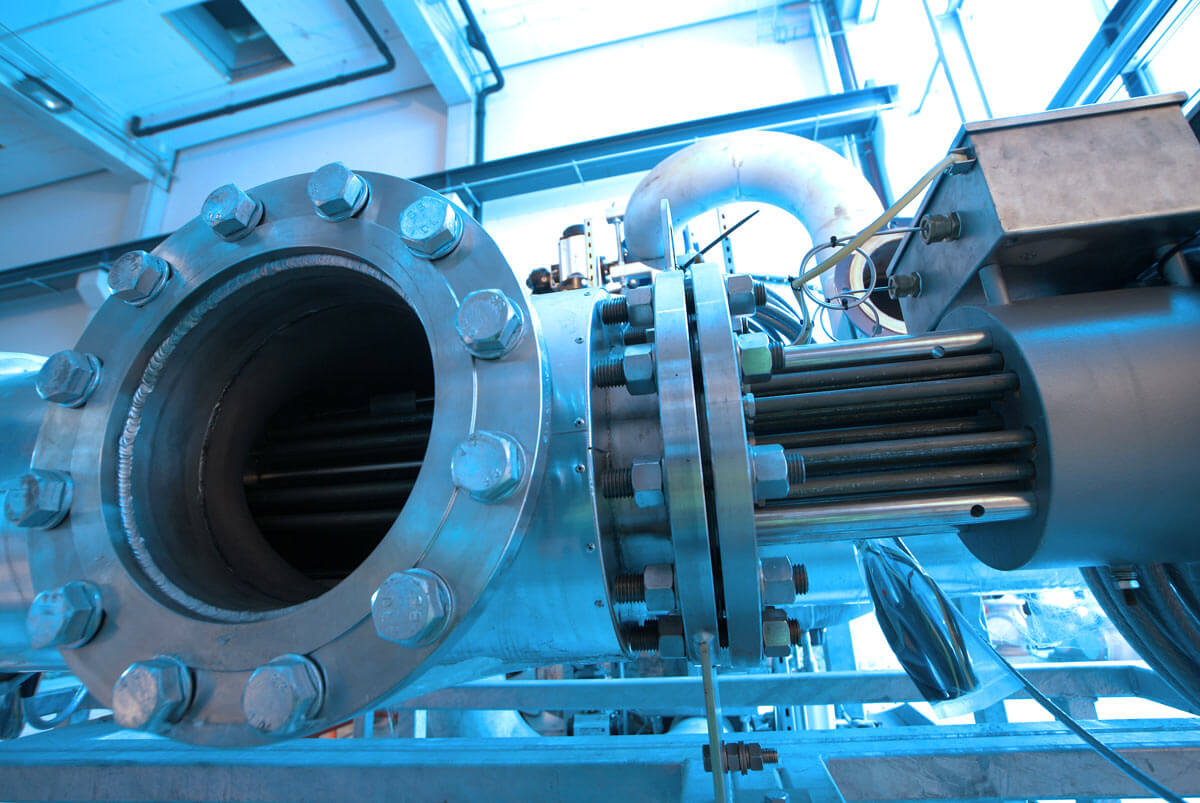

Electropolishing Energy Generation Equipment

For oil and gas, solar energy, and nuclear energy applications, electropolishing enhances corrosion resistance and reduces contamination.

- Reactor vessels

- Heat exchangers

- Blenders

- Storage tanks

- Piping and tubing

- Solar panels

- Semiconductors

Electropolishing Aerospace Components

Miles above the earth, there’s little room for error. Advanced aerospace technology, sophisticated avionics, and complex aircraft equipment depend on precision components to accomplish their missions smoothly and safely. EMI is one of few operations in the United States to offer Nadcap-approved electropolishing. Electropolishing aerospace components provide the precise smoothness and finish required for critical aerospace components, including:

- Helicopter blades

- Flight control systems

- Communication systems

- Navigation systems

- Weather systems

- Fasteners

- Connectors

- Engine components

- Heat exchangers

- Collision avoidance systems

For more information on electropolishing application solutions and electropolishing industries served, contact us today!

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100