What is Electropolishing?

Electropolishing, also known as electrochemical polishing, is an electrochemical process that removes surface imperfections and impurities such as burrs, microcracks, stains, heat tint, and oxide scaling from components, parts, and equipment made of a wide variety of metals. Electropolishing leaves vital parts and critical components ultra-clean, super-smooth, and highly resistant to corrosion.

How does Electropolishing Work?

Here’s how electropolishing works: Metal parts are placed and secured in a special rack, then submerged into a specially blended chemical bath. An electrical current is applied to the part. The charge causes a chemical reaction that smooths the part’s surface by removing an extremely thin layer of metal at a controlled, uniform rate. The electropolishing process can be monitored and completed to meet exacting specifications for cleanliness, smoothness, and corrosion protection. Your stainless steel — such as 300 series and 400 series stainless steel — and other metal parts, components, and equipment need to be as perfect as possible.

Microscopic cracks, bumps, and burrs on life-saving surgical instruments, intricate avionics, and sensitive nuclear reactor piping can cause major problems. For more than two decades, Electro-Max, Inc. (EMI) has delivered high-quality electropolishing, or electrochemical polishing, services that expertly, efficiently, and effectively eliminate surface imperfections and impurities that can compromise the fit, finish, function, and durability of parts made of stainless steel, titanium, nickel, aluminum, and other metals. You can also learn more about the industries served for electropolishing here!

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

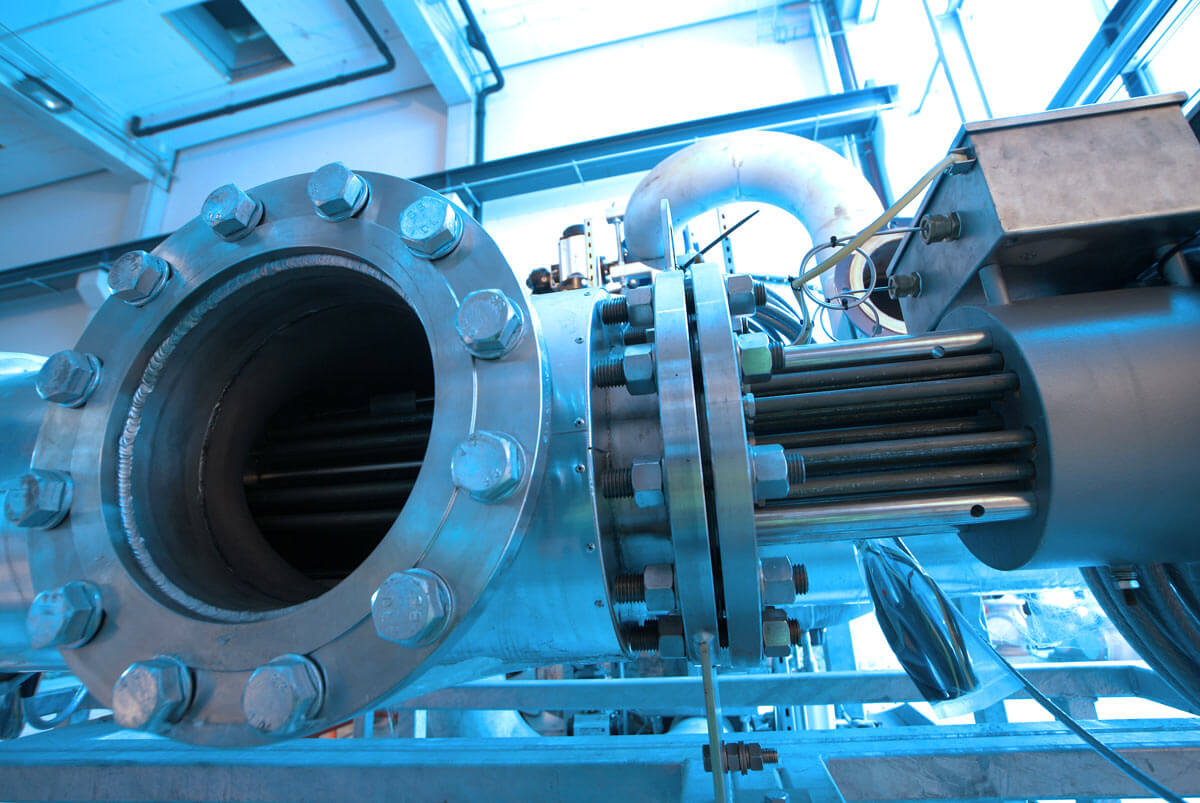

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100