Nuclear Electropolishing & Passivation Services

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important. Nuclear electropolishing services increase the surface smoothness to promote easier cleaning by removing any small burrs or protrusions left after the manufacturing process. Electropolishing can also reduce radioactive contamination when compared to an untreated surface due to a decreased absorption rate. Common practice utilizes electropolishing as a stress relieving operation after mechanical polishing. Call to request a quote today on your nuclear electropolishing and passivation service needs.

Nuclear Industry Usage

The process can also be used for subsequent decontamination after the part has been in use. The process is used to reduce radioactive contamination by removing a fine layer of surface material and in the process flushing away any embedded or the surface contaminants.

Why Choose Electro-Max for the Nuclear Industry?

Typically, nuclear applications will require a preclean via pickling or passivation to remove any free iron or other surface contaminants. This process will prepare the surface for electropolishing by providing a clean contaminant free surface so the electropolishing process can achieve its full potential.

Electro-Max, Inc. has decades of experience in nuclear electropolishing and passivation services. EMI is an ISO 9001, ISO 13485, ISO 14001, 10-CFR 21 and Nadcap approved facility where quality and integrity are at the core of our business practices.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn More

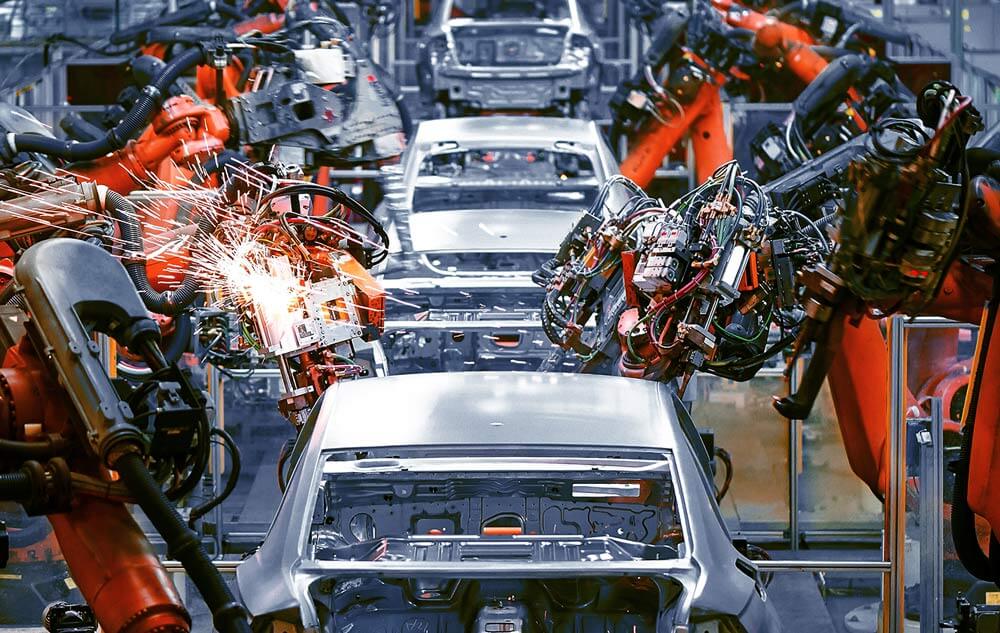

Automotive

In the dynamic realm of automotive engineering, precision, durability, and top-tier performance are imperative. To meet the rigorous standards of the Automotive industry, the specialized processes of auto parts electropolishing and automotive parts passivation are crucial.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100