Abrasive Media Blasting Metal Finishing Services

What is Abrasive Media Blasting Metal Finishing?

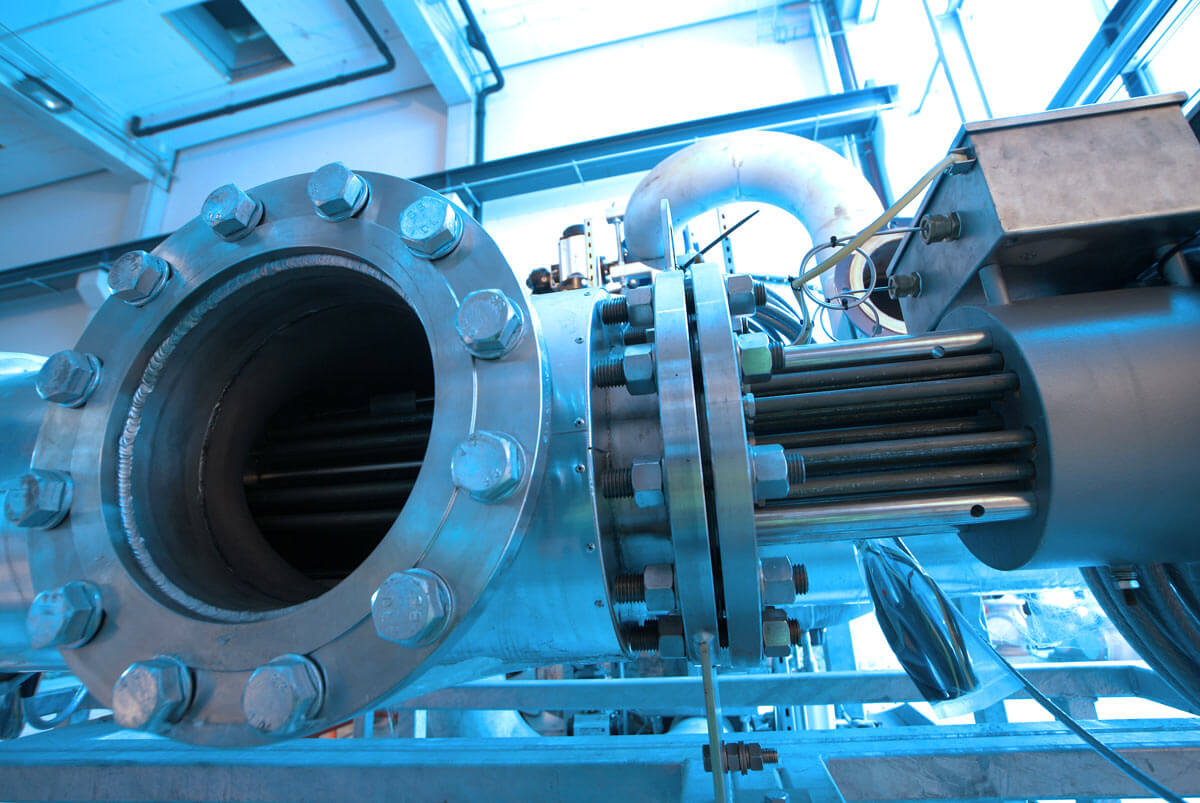

Electro-Max, Inc. now offers abrasive media blasting metal finishing services for small stainless steel component parts up to 24″ in length and width. We currently offer a variety of surface, metal finishing services such as pickling, passivation, and electropolishing but no other complimentary services such as blasting. Many of our customers in the nuclear, medical, and food industries send their parts to many vendors to reach an endpoint. We are trying to lessen the time your parts spend in transit and also save on shipping and labor costs associated with managing several different suppliers or vendors. We provide a range of surface preparation methods such as pickling, passivation, and electropolishing but now we offer abrasive blasting services for small components made of stainless steel. We are looking to expand into other alloys as we move forward. Electro-Max will offer aluminum oxide media blasting for stainless steel components at this time.

Abrasive Media Blasting

Grit blasting provides an economical choice that is used to remove any foreign material such as scale, oxides, and other contaminants that may be left on your part after manufacturing or the machining process.

Abrasive media blasting metal finishing is a process that provides a matte surface finish without any substrate material removal or chemical contamination. After being blasted to remove all foreign bodies our passivation service removes any residual film leftover from the process and seals the surface of stainless steel back up creating a corrosion-resistant layer that will hold up in even the toughest of conditions. Many of our current customers are sending their parts elsewhere to be blasted so we have added this as a service extension to what we already do here at EMI. Our turnaround time is 3-5 days with expedited services available. Electro-Max, Inc. will provide free samples for your approval to ensure we meet your expectations.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100