Vapor Blasting

Wet Blast and Abrasive Metal Finishing

What is Vapor Blasting?

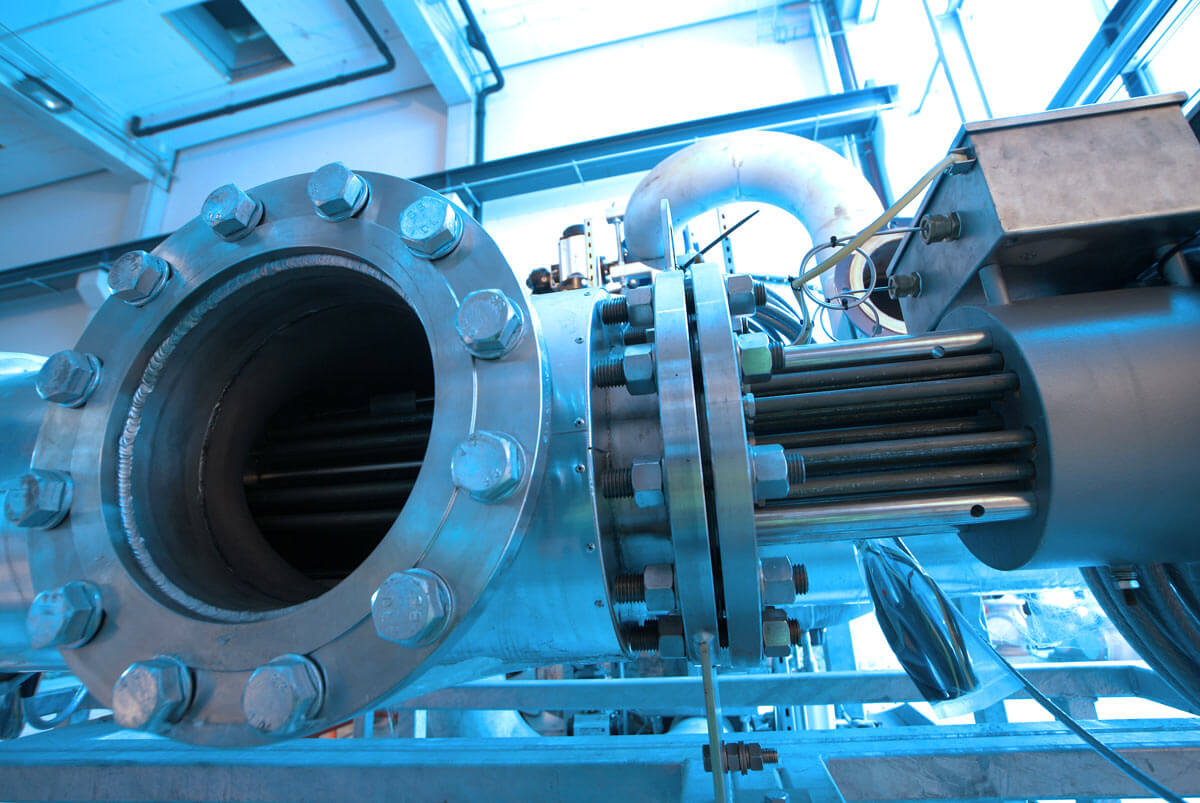

Vapor blasting (also known as wet blasting, liquid honing, or dustless blasting) is a process that uses pressurized water and abrasive material to remove contaminants, corrosion, residue or coatings from a surface. The vapor blasting process provides the highest quality soft surface finish. It is commonly used for cleaning aerospace parts and surfaces.

How Does Vapor Blasting Work?

Pressurized water and abrasive are combined into a slurry. Pressurized air blasts the mixture of water and abrasives at the surface of the part, removing coating or other contaminants. The water droplets weigh down the fine particles created from the impact, preventing dust. The vapor blasting process leaves the surface clean, smooth, and preserved from media impregnation.

Why Vapor Blasting?

Compared to dry blasting, vapor blasting allows for a wide range of media from very fine to coarse and a variety of densities. Additionally, vapor blasting allows parts to be degreased blasted at the same time by using hot water and soap. Water flushes out the abrasive, washing out sediment or residual media.

Since wet blasting is dustless, it is safer to remove hazardous materials like radioactive or poisonous materials or asbestos. Dustless blasting also makes setup easier and reduces the cleanup costs. Without static cling, vapor blasting creates a cleaner surface than its dry counterparts. Wet blasting is also ideal when dry blasting would be too destructive and softer media are required to protect the surface.

With over 20 years’ experience and a commitment to quality standards and processes, Electro-Max, Inc. provides the best customer service, unsurpassed quality and superior vapor blasting services. EMI is NADCAP accredited, fully registered to ISO9001:2015 and complies with ASTM B600 and other customer specific standards.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100