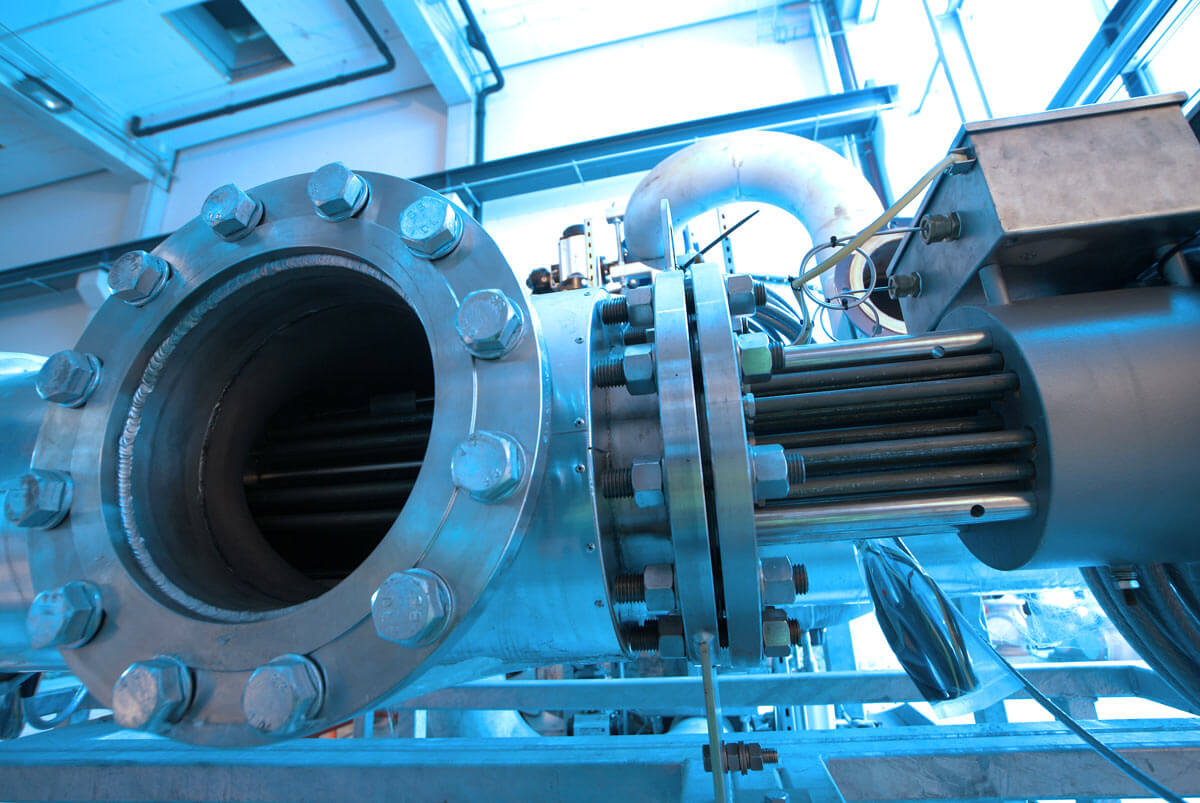

Electropolishing & Passivation Services for Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more. These advantages contribute to the overall reliability, longevity, and performance of the equipment, ensuring safe and efficient operations in this demanding industry.

Benefits of Electropolishing Services for Oil & Gas

What are the benefits of electropolishing stainless steel services in the Oil & Gas industry?

Electro-Max, Inc.’s electropolishing stainless steel services offer several benefits for the oil and gas industry. Here are some ways in which electropolishing is beneficial:

Corrosion Resistance:

Stainless steel is already known for its corrosion resistance, but electropolishing takes it a step further. Electropolishing removes surface imperfections, including embedded contaminants, oxides, and scale, creating a smoother and more uniform surface. This process improves the stainless steel’s resistance to corrosion, making it highly suitable for harsh environments encountered in the oil and gas industry, such as offshore drilling platforms and pipelines.

Cleanability and Sanitization:

Electropolishing creates a surface that is easier to clean and maintain. The smooth, microscopically level surface reduces the adhesion of contaminants, making it easier to remove dirt, oil, and other substances during routine cleaning processes. This is particularly important for equipment and components used in oil and gas operations that require frequent cleaning or sterilization to ensure proper functioning and avoid contamination.

Improved Surface Finish:

Electropolishing enhances the surface finish of stainless steel, giving it a bright, smooth, and aesthetically pleasing appearance. This is beneficial in the oil and gas industry, where components may be visible or inspected visually. A polished surface not only improves the overall appearance of the equipment but also facilitates visual inspection, making it easier to identify any defects or signs of wear.

Passivation:

Electropolishing can be used as a passivation method for stainless steel. Passivation is a process that removes free iron and other surface contaminants, forming a protective oxide layer. This oxide layer further enhances the corrosion resistance of stainless steel. In the oil and gas industry, where exposure to corrosive elements is common, passivation through electropolishing helps extend the lifespan of equipment and reduces the risk of premature failures or leaks.

Stress Relief:

Electropolishing can also provide stress relief to stainless steel components. The process can help reduce the occurrence of stress-induced corrosion, cracking, or other failure mechanisms that can arise due to manufacturing processes or operational stresses. This is particularly relevant for oil and gas equipment subjected to high pressure, temperature variations, and mechanical stresses.

Visual Inspection:

Electropolishing improves the surface finish of stainless steel, providing a bright and visually appealing appearance. This is beneficial in the oil and gas industry, where visual inspection of equipment is necessary for quality control and maintenance purposes. A polished surface makes it easier to identify any defects, signs of wear, or surface abnormalities that could compromise the performance or integrity of the components.

Overall, electropolishing of stainless steel provides improved corrosion resistance, enhanced cleanability, improved surface finish, and stress relief, all of which are highly beneficial for the oil and gas industry. These advantages contribute to the durability, reliability, and performance of stainless steel equipment used in various applications, ranging from pipelines and valves to tanks and processing equipment.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn More

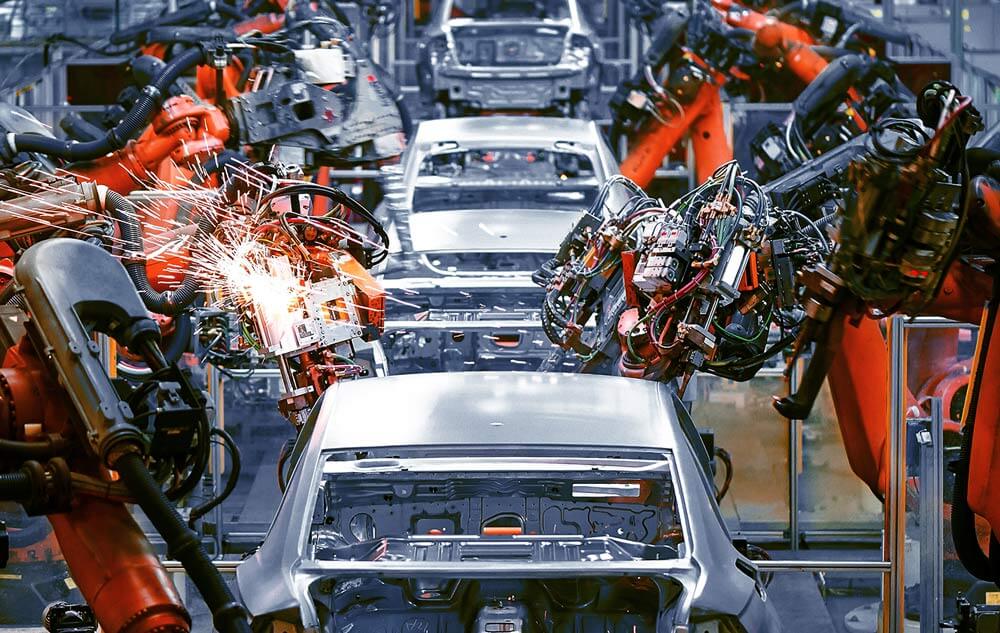

Automotive

In the dynamic realm of automotive engineering, precision, durability, and top-tier performance are imperative. To meet the rigorous standards of the Automotive industry, the specialized processes of auto parts electropolishing and automotive parts passivation are crucial.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100