Aerospace Electropolishing & Metal Finishing Services

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts. Electropolishing has become a tried-and-true solution for improving the corrosion resistance of stainless steel while also improving its structural integrity. Turn to Electro-Max, a leading provider of metal finishing services, for best-in-class electropolishing services and metal finishing services to aerospace manufacturers across the industry.

Aerospace Metal Finishing & Deburring Services

Failure of critical aircraft components can be catastrophic in the wrong circumstances. In response, the aerospace industry has created a range of manufacturing standards, and various government agencies have imposed regulations on manufacturers. Failure to do so can result in severe penalties, and in the event of part failure, the results could be deadly.

What are the Benefits of Electropolishing Services in the Aerospace Industry?

For decades, electropolishing has been the answer to the challenges of the aerospace industry. This process, in which an electrical current is run through metal parts immersed in a chemical solution, offers a range of benefits to aerospace manufacturers needing to offer an extra level of strength to their metal components.

- Electropolishing helps to strengthen metal components by closing up microscopic fissures and imperfections in the surface of the metal.

- Electropolishing improves the corrosion resistance of a range of different materials, including stainless steel.

- Electropolishing doesn’t involve the use of a coating, meaning that electropolished components won’t peel or abrade over time.

- Metal parts do not experience any distortion during the electropolishing process, making it an ideal option for the most delicate metal parts.

- The electropolishing process removes a predetermined amount of surface material of the finished part at a controlled, uniform rate. Because of this, electropolishing is also an excellent way of removing burrs or other flecks of metal left behind during the manufacturing process.

Alloys

We provide electropolishing services on the following alloys:

- 301

- 302

- 303

- 304

- 305

- 316

- 321

- 347

- 304 Sintered

- 318 (2205 Duplex)

- 330 (cast)

- 410

- 416

- 418

- 420

- 430

- 440A

- 440C

- 446

- 455

- 465

- 5-f (Like 416)

Passivation Services for Aerospace

We also provide passivation services to aerospace manufacturers. Stainless steel components generally come into contact with contaminants like oil or grease that can harm the protective chromium oxide layer that naturally forms. Passivation is a metal finishing process that helps that layer form faster and thicker for improved corrosion resistance.

Depending on the application in question, passivation might be a better fit for your metal components. Passivation uses no electricity during the treatment process. And in contrast with electropolishing, passivation leaves the appearance of the material unchanged.

Electro-Max, one of the leading electropolishing companies serving the aerospace industry, holds a range of industry certifications:

- ISO 9001:2015 Registered

- ISO 13485:2003 Certified Compliant

- ISO 14001:2015 Registered

- AS9100 Compliant

- 10CFR21 Compliant

- ITAR Compliant

In addition, we also hold NADCAP Certification Aerospace Quality System (AC7004) certification, making us one of the few companies in the industry certified to provide electropolishing services to the aerospace industry.

Learn more about our aerospace electropolishing and metal finishing services and how we can help you achieve the next level of quality. Contact us today.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

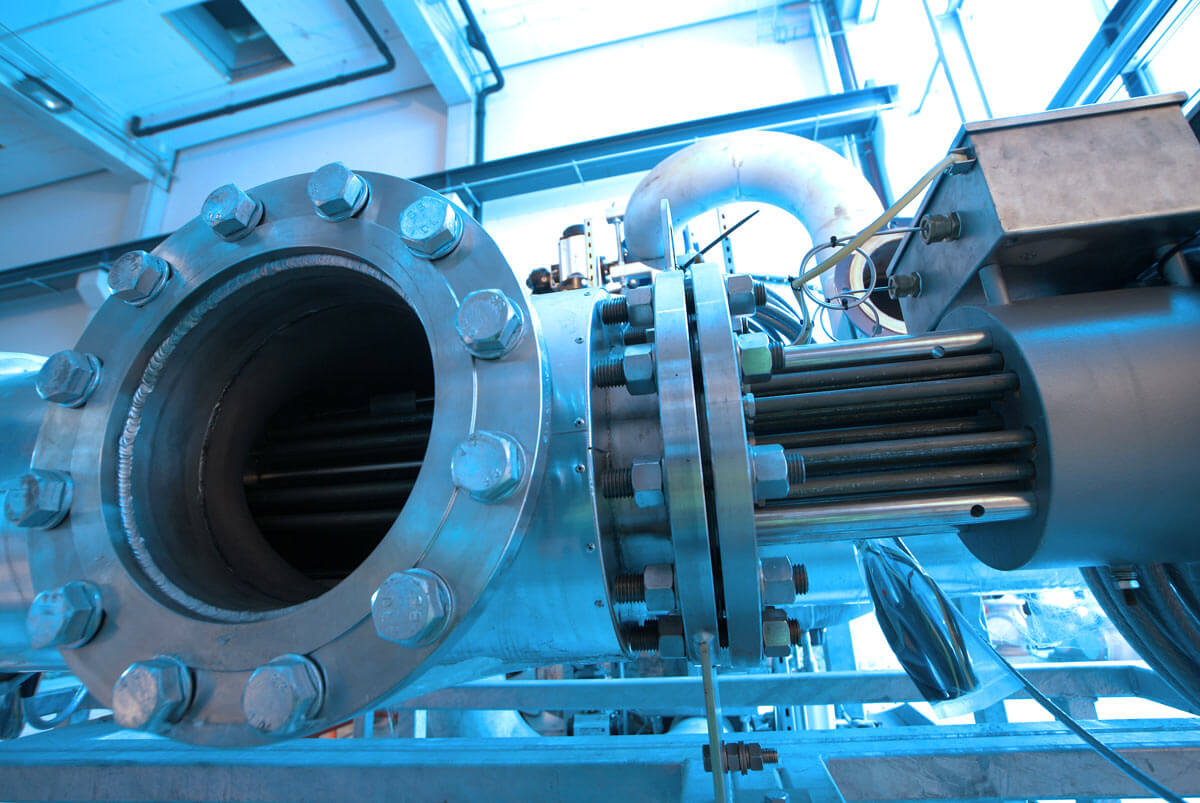

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn More

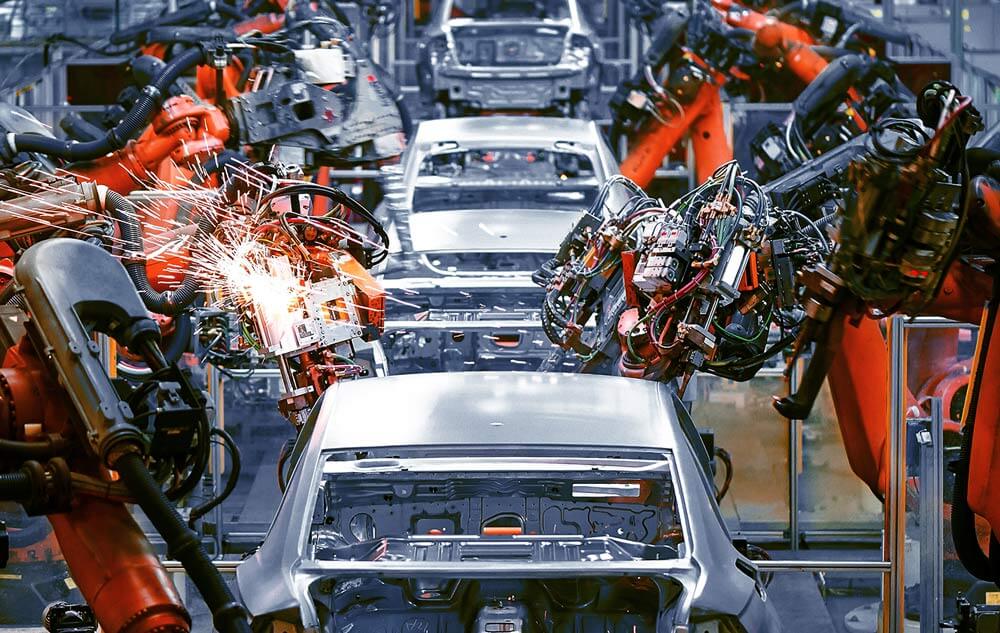

Automotive

In the dynamic realm of automotive engineering, precision, durability, and top-tier performance are imperative. To meet the rigorous standards of the Automotive industry, the specialized processes of auto parts electropolishing and automotive parts passivation are crucial.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100