Benefits of Passivation for Stainless Steel & Metal Alloys

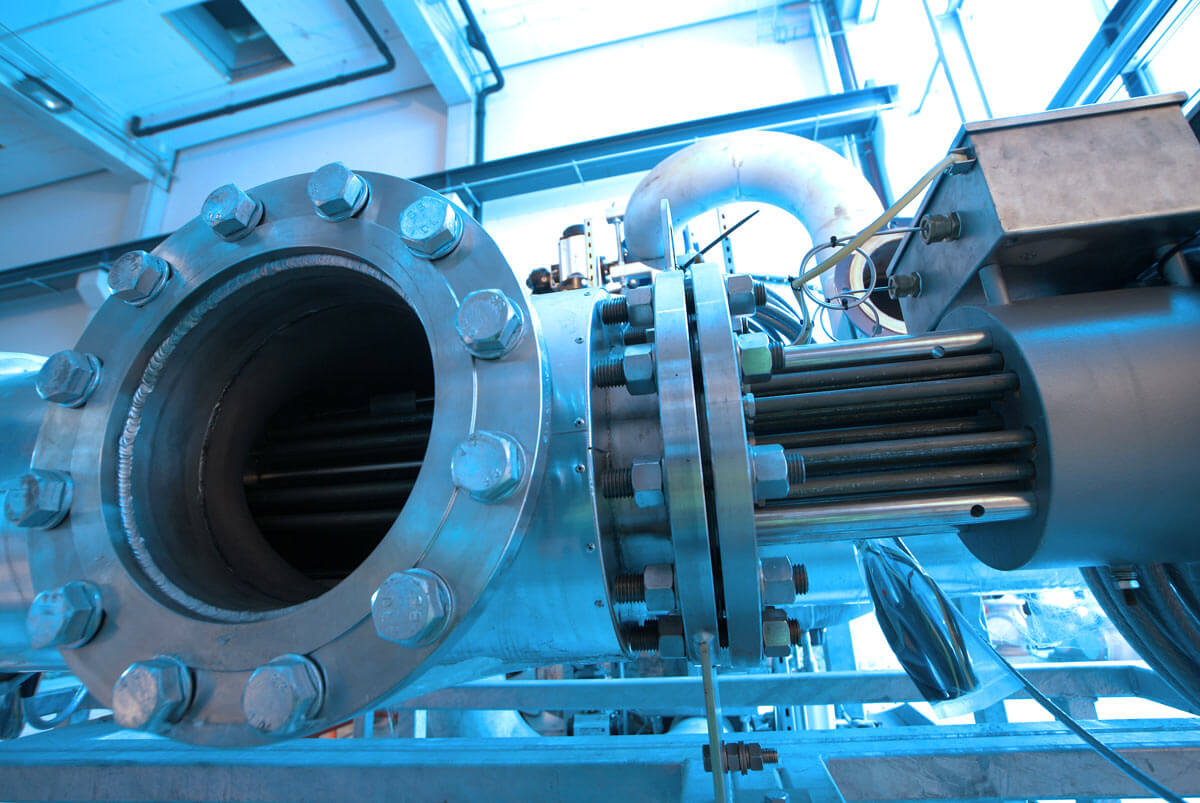

There are many benefits of passivation for stainless steel and metal alloys. When stainless steel is left to the elements or undergoes a manufacturing process, it is frequently left with some level of surface contamination, particularly in the form of iron particles. If left in place, these particles can corrode over time, compromising the integrity of the material. The stainless steel can be cleaned, but the cleaning process can also create hazards that can compromise its performance.

One of the methods around this problem is passivation. Many metals, including stainless steel, already have a thin oxide layer to make them more resistant, or “passive,” to corrosion. Passivation increases the thickness of that layer to increase the level of protection against rust and corrosion on the material.

Stainless Steel Passivation

What are the Benefits of Passivation for Stainless Steel & Other Metal Alloys?

Stainless steel passivation, and passivation for other metals and metal alloys, offers a range of benefits beyond improved corrosion resistance for stainless steel components, including:

Remove Surface Contamination

The chemical cleaners and tools used to remove surface contamination can themselves inflict damage on the surface of stainless steel. Passivation is able to remove surface contaminants at a molecular level without damaging the surface of the material.

Reduce the Risk of Contamination

If your stainless steel components are being used in a manufacturing process requiring high levels of purity, such as pharmaceuticals, then keeping those components clean is absolutely critical. Passivation can help by removing other compounds aside from iron to keep your components highly clean.

Save Money and Downtime

By regularly treating your stainless steel components through passivation, required system shutdowns can be both shorter and less frequent. And by preserving the integrity of your stainless steel components, unplanned system shutdowns are a reduced risk. Your manufacturing facility will have increased uptime and reduced downtime, which means boosted revenue and reduced costs.

Passivation can be a highly useful tool to keep your manufacturing system running smoothly. Contact us today to learn more.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100