Passivation Applications & Industries Served

Passivation – a chemical process that can increase the corrosion resistance of metal – has applications in numerous industries and products. EMI’s passivation services, which adhere to a range of industry standards, can provide you with the level of durability you need in even the most corrosive environments.

Passivating Machined Parts

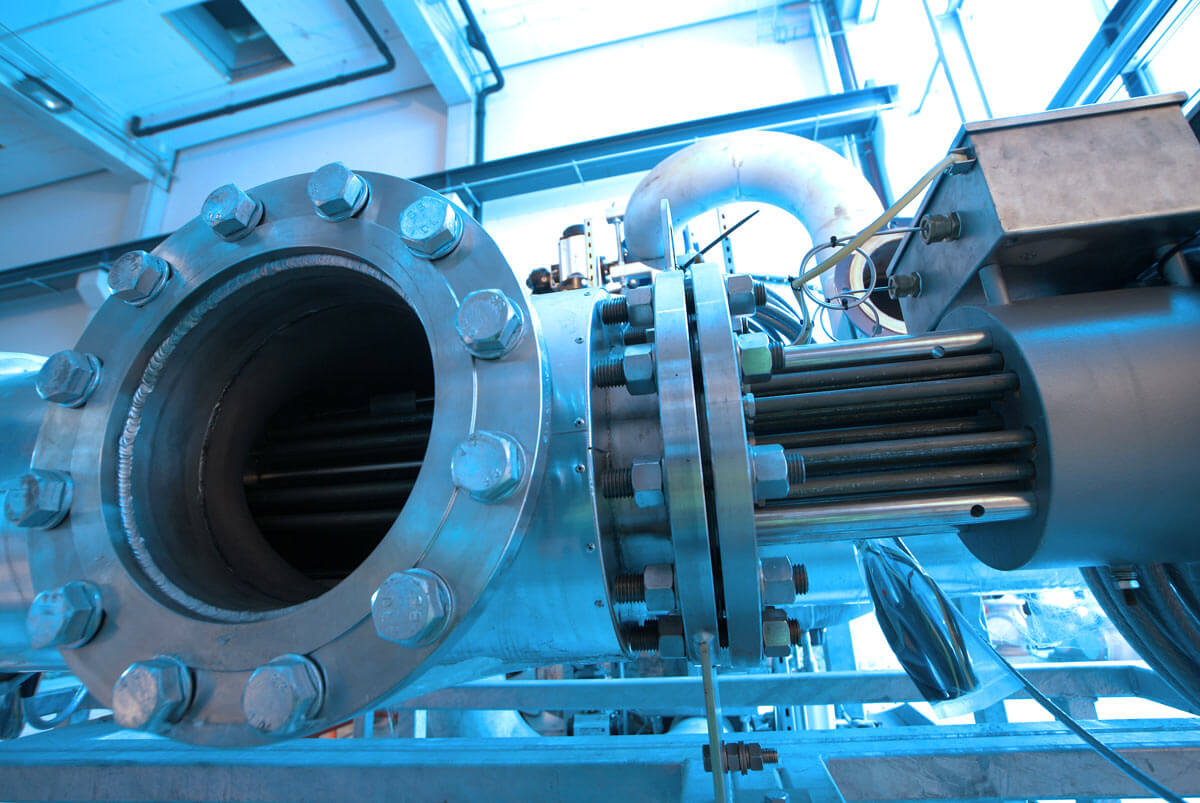

The machine tool industry has made significant use of passivation of machined parts. Passivation can add to the outer protective layer naturally produced by many metal alloys on a nanometer scale, giving machined parts increased corrosion resistance while allowing the finished part to stay within tolerance. Passivation is suitable for a range of machined components, including:

- Drawings

- Rods

- Fittings

- Tanks

- Discs

- Stampings

- Weldments

- Castings

- Spinnings

- Forgings

- Fasteners (screws, bolts and washers)

- Pipes and tubing

- Valve stems and bodies

Passivation for Food, Beverage, & Dairy Processing Equipment

The manufacturing and processing environments found in the food and dairy processing industry frequently involve temperatures and substances that can do a lot to foster corrosion in steel components. EMI provides first-class passivation services for the food, beverage and dairy processing industries. We have experience with passivation of a range of components, including:

- Filters

- Screens

- Tubing

- Dryers

- Mixers

- Piping

- Product Trays

- Storage tanks

- Product impellers

- Fermentation vessels

- Dry product delivery systems

Passivation for Cleanroom Manufacturing Facilities

Cleanroom facilities, particularly in the semiconductor industry, require non-contaminating surfaces in all areas, even in situations where caustic chemicals and solutions are used in manufacturing processes. To prevent metals used in cleanroom settings from corroding over time, passivation is frequently employed. We have provided quality passivation services for a range of products and components used in cleanroom manufacturing facilities, including:

- Equipment consoles

- Light fixtures

- Vacuum chambers

- Manufacturing & processing equipment

- Gas & fluid distribution systems

- Exposed electrical conduit & outlet boxes

- Tables, chairs, & waste containers

Passivation for Medical Devices

Medical devices can’t afford to have corrosion contaminate delicate electronics and components. EMI has provided passivation services for a range of medical devices and equipment, including:

- Surgical instruments, including:

- Scalpels

- Staplers

- Biopsy Instruments

- Battery components

- Orthopedic implants

- Bone screws

- Pacemakers & defibrillator electronic circuit boards

- Robotic instruments

Passivation for Aerospace Components

The aerospace industry – one of the most highly regulated industries in the world – has strict requirements regarding its equipment and components. EMI has experience providing passivation services in compliance with AMS 2700 and QQ-P-35 standards. Let us provide passivation services for your aerospace components, including:

- Aircraft sensors

- Helicopter blades

- Turbine assemblies

- Fasteners & Connectors

- Heat exchangers

- Navigation, communication, & weather systems

- Engine components

EMI’s passivation services are second to none. We have the expertise and capacity to handle a full range of passivation services for the widest range of materials, components, and industries. Contact us today to learn more.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100