The Value of Electropolishing and Passivation for Inconel Materials

What is Inconel?Inconel is a family of high-performance, nickel-chromium-based superalloys known for their exceptional resistance to extreme temperatures, corrosion, and mechanical stress. These materials are composed of a combination of nickel, chromium, and other elements, making them a popular choice in various demanding applications.

Industries and Applications of Inconel

Inconel materials find extensive use in several industries and applications, including:

- Aerospace: Inconel's high-temperature and corrosion-resistant properties make it a preferred choice for components in aircraft engines and gas turbine systems.

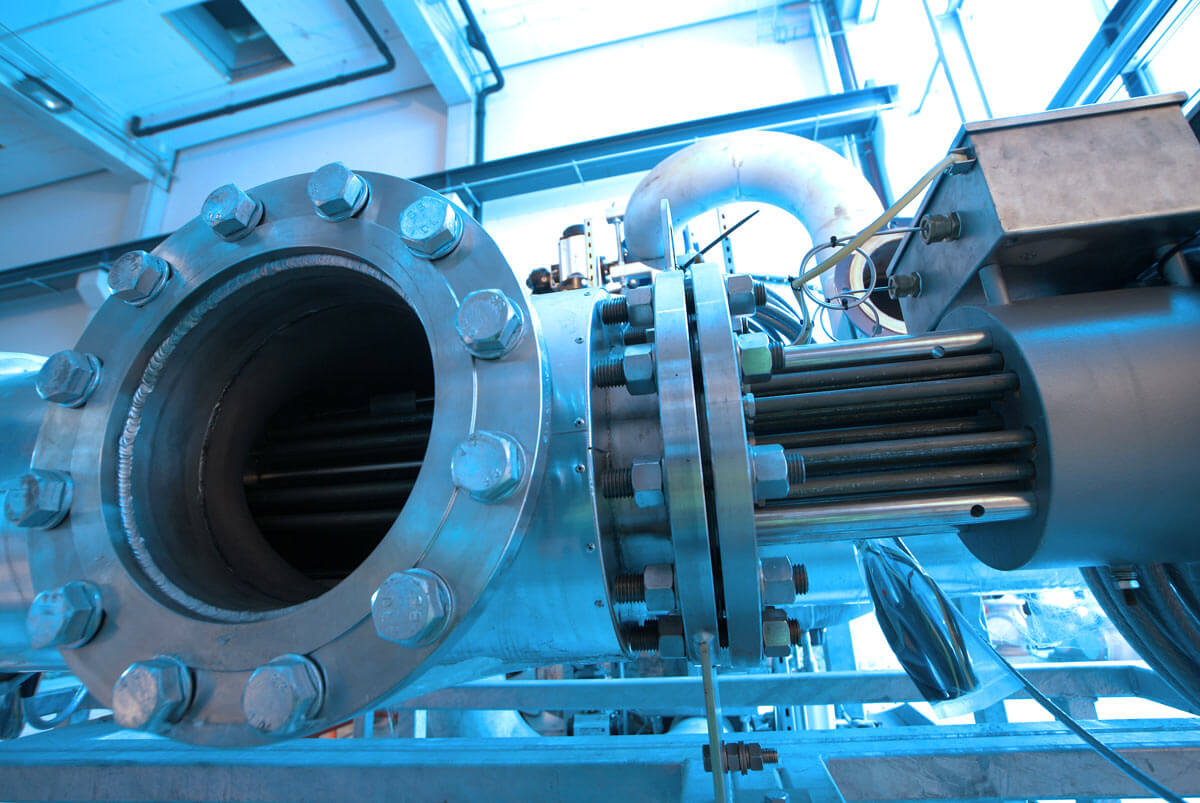

- Chemical Processing: Inconel resists corrosion from harsh chemicals and acids, making it suitable for chemical plant equipment, reactors, and piping systems.

- Oil and Gas: Inconel is used in oil and gas extraction equipment, where it can withstand high-pressure, high-temperature, and corrosive environments.

- Marine Industry: Inconel is used in marine applications due to its resistance to saltwater corrosion, making it ideal for marine equipment and offshore structures.

- Medical Devices: Inconel's biocompatibility and resistance to sterilization processes make it valuable in the medical industry for implants and surgical instruments.

- Power Generation: Inconel materials are used in power plants, particularly in components exposed to extreme temperatures and harsh operating conditions.

Importance of Electropolishing Inconel Material

Electropolishing Inconel material is crucial for several reasons:

- Improved Corrosion Resistance: Inconel, while highly corrosion-resistant, can benefit from electropolishing to further enhance its resistance to various corrosive agents, especially in applications where the material is exposed to harsh chemical environments.

- Surface Finish: Electropolishing provides Inconel components with a smoother and more aesthetically pleasing surface finish. This can be essential in industries like aerospace and medical devices, where precise surface conditions are critical.

- Cleaning and Sterilization: Electropolishing facilitates easier cleaning and sterilization of Inconel components, making it indispensable in medical and food processing applications.

Importance of Passivating Inconel Material

Passivation of Inconel materials is essential for:

- Corrosion Prevention: Passivation creates a protective oxide layer on the surface of Inconel, further improving its corrosion resistance. This is particularly valuable in applications where the material is exposed to aggressive chemical or saltwater environments.

- Maintaining Surface Integrity: Passivation helps maintain the surface quality and original dimensions of Inconel components. It preserves the integrity of the material, making it suitable for critical applications in aerospace, oil and gas, and more.

Why Choose Electro-Max for Electropolishing Inconel Services?

Electro-Max, Inc. specializes in the finishing of stainless steel and Inconel materials through electropolishing and passivation. When you choose Electro-Max for electropolishing Inconel services, you benefit from:

- Expertise: Our team possesses extensive knowledge and experience in electropolishing Inconel materials, ensuring the highest quality results.

- Nadcap Approved: Electro-Max is one of the few in the USA with Nadcap approved electropolishing processes, guaranteeing the highest industry standards.

- Comprehensive Services: In addition to electropolishing, we offer complementary services such as passivation, stainless steel pickling, and degreasing, providing a one-stop solution for all your metal finishing needs.

- Superior Customer Interaction: We prioritize your satisfaction, offering excellent customer service, value, and top-notch quality in every project.

In conclusion, Inconel materials are prized for their exceptional properties in demanding industries. Electropolishing and passivation further enhance the value of Inconel by improving corrosion resistance, maintaining surface integrity, and ensuring surface aesthetics. When it comes to electropolishing Inconel materials, Electro-Max, Inc. stands out as a trusted and experienced partner, offering Nadcap approved processes and comprehensive services to meet your specific needs.

Electro-Max, Inc. is your go-to for all electropolishing services in a variety of industries! Certain industries need high levels of durability and corrosion resistance in their finished parts. Turn to Electro-Max, Inc. for first-class electropolishing and passivation services.

Food & Beverage

Don’t put your equipment at risk! Electropolishing and passivation services from Electro-Max are proven solutions for improving the corrosion resistance of food-grade metal parts.

Learn More

Aerospace & Defense

Aerospace has some of the most stringent requirements of any industry with respect to the structural integrity of metal parts.

Learn More

Oil & Gas

By utilizing electropolishing services for stainless steel components, the oil and gas industry can benefit from improved corrosion resistance, efficient cleanability, enhanced surface cleanliness, visual inspection capabilities, and more.

Learn More

Medical

In the ever-evolving landscape of medical technology, precision, cleanliness, and longevity are paramount. Electro-Max, Inc. stands at the forefront, offering specialized medical electropolishing services and medical passivation services.

Learn More

Nuclear

Electropolishing and passivation are both widely used processes in the nuclear industry. Often used for parts that will be subjected to radioactive environments where surface smoothness cleanability is very important.

Learn More

Pharmaceuticals & Bio-Processing

In the high-stakes industries of pharmaceuticals and bio-processing, precision, purity, and product quality are non-negotiable.

Learn MoreDo you have questions?

Ask an expert today.

Give us a call or fill out the form below and one of our team members will be in touch as soon as possible.

*marks required fields

Or Give Us a Call

(847) 683-4100